Many industrial processes rely on steady vacuum pressure. Leaks disrupt that. Find them with ultrasound.

What are Vacuum Leaks Costing You?

Vacuum leaks waste energy, drive up costs, and hurt product quality.

When leaks go undetected, pumps work harder to maintain pressure, driving up energy consumption and accelerating wear and tear on the seals, bearings, and other critical components.

Unstable vacuum pressure creates inconsistencies in the production process, leading to contamination risks, quality defects, lower yields, and reduced overall reliability.

Risks associated with a leaky vacuum pressurized system

- Higher energy consumption – Pumps work harder to compensate.

- Process inefficiencies – Unstable vacuum pressure slows production.

- Equipment damage – Increased wear on pumps, seals, and system components.

- Product defects – Poor vacuum control impacts quality and consistency.

Don’t wait for problems to arise. Find vacuum leaks with Acoustic Imaging.

Traditional methods for vacuum leak detection are slow and unreliable. Acoustic imaging provides a non-intrusive, real-time way to pinpoint leaks, even in noisy industrial environments.

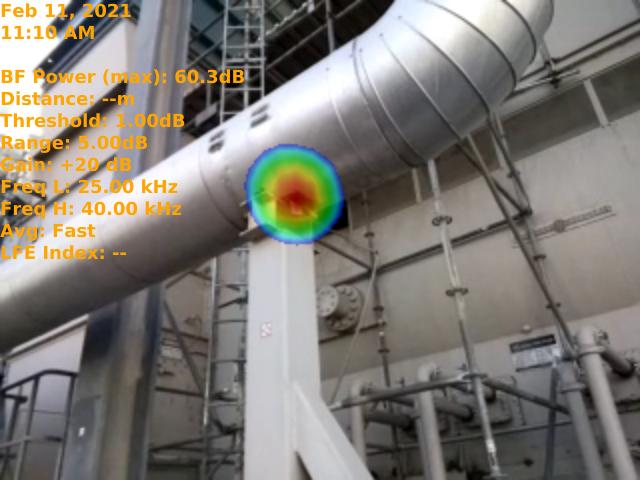

Acoustic imaging cameras work by turning the high-frequency ultrasound signals produced by the differential pressure of a vacuum leak into a visual image so it can be tagged and repaired.

- Instant detection – no guesswork. See exactly where leaks are.

- Designed for loud environments – No need for shutdowns or isolation.

- Improve efficiency and reliability – Reduce energy waste and equipment wear and tear.

Finding Vacuum Leaks with Acoustic Imaging

Plan Your Survey

Begin by reviewing your vacuum system layout and identifying potential leak points. Map out the areas you’ll inspect to ensure complete coverage and a more efficient survey.

Scan & Tag

Use acoustic imaging to quickly detect and visualize vacuum leaks—even in hard-to-reach areas. Tag each leak location to prioritize repairs and keep your maintenance team on track.

Repair & Review

Fix the tagged leaks, then perform a final scan to confirm they’re fully resolved. This ensures restored vacuum pressure, minimized energy waste, and a healthier bottom line for your operations.

Keep Your Vacuum System Leak-Free

Stop pressure losses before they impact production. Get a demo today.