SonaVu™ for Invisible Steam Leaks & More!

Have you ever been inside a pulp and paper factory? What about the dryer section of a paper machine? It’s loud… like really loud! The noises from the paper manufacturing process resonate around the dryer making it extremely difficult to pinpoint the source of any one particular noise.

During routine inspection, this paper factories maintenance and reliability team noticed an undesirable clicking noise coming from the paper machine. From their historic knowledge of the machine, they knew the machine didn’t typically make that clicking sound, and because it was making that sound, something had likely broken inside of the machine.

To find out what had broken, and perform the necessary root cause analysis, the maintenance and reliability team would need to find the exact location of the clicking, while the machine was running. A task that would prove very difficult without the assistance of modern condition monitoring technologies.

Thankfully, they were being visited by a member of the SDT Ultrasound Team that day, and that member brought their SonaVu™ Acoustic Imaging Camera!

An Acoustic Imaging Camera is a new condition monitoring technology that visualizes sound and ultrasound. This new technology is being utilized by maintenance and reliability teams around the world to pinpoint the location of compressed air leaks, electrical faults, diagnose the health steam traps and steam systems, perform tightness testing, and much more.

With the power of acoustic imaging technology at their fingertips, this paper factories maintenance and reliability team had a brilliant thought. If acoustic imaging could be used to locate other faults that produce ultrasound signals, why couldn’t it be used to find this clicking? After all, the clicking produces impacting, one of the three forces (friction, impacting and turbulence) that produce ultrasonic signals.

So, they got to work, scanning around the inside of the dryer section of the paper machine. The team was pretty sure the clicking was coming from one of two rotary union valves. Steam passes through these valves on the way to dryer cans. They are involved in an integral part of the paper manufacturing process, and failures on these valves would lead to costly unplanned downtime.

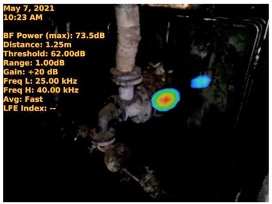

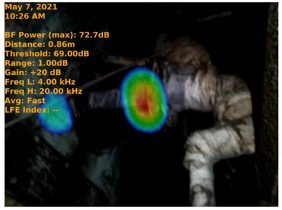

The following images were taken with a SonaVu on the two different rotary union valves. By adjusting the threshold to the noise level in the area, the maintenance and reliability team was able to pinpoint a defect on each of the valves within 5 minutes of performing the acoustic imaging inspection.

The first fault the maintenance and reliability team located was not the clicking noise that initially led them to perform the inspection. It was actually something much less detectable, and much more dangerous… Human hearing detects sounds in the frequency range from 20 Hz to 20 kHz. As seen in image 1, this defect is outside of the range human hearing and, therefore, undetectable without the use of ultrasound technology.

The first fault detected is an invisible steam leak, and it is VERY hot. Hot enough to burn through clothes and melt human flesh. You do not want to accidently walk into one of these. Thankfully, the maintenance and reliability team were able to find this fault during the inspection and avoid any injury.

The second fault the maintenance and reliability team located was the pesky clicking noise they initially set out to find. As seen in the image captured with the SonaVu, this defect is well in the range of human hearing.

After pinpointing the fault, the maintenance and reliability team was able to determine the fault on the rotary union valve was in fact mechanical. They were able to perform the simple maintenance necessary to repair the fault during the next routine shutdown, and in doing so, avoided unplanned downtime!

Once again, the SonaVu Acoustic Imaging Camera has proven its effectiveness monitoring the condition of all sorts of assets widely utilized in industry, this time it was valves.